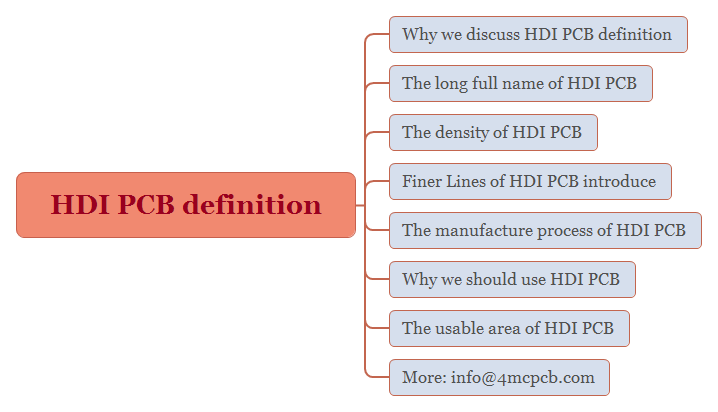

Why we discuss HDI PCB definition

HDI PCB definition is basic common sense.

Compare with conventional PCB board, there were many people don’t know HDI PCB.

Now smart phone has become more and more normal, if you ask smart phone design engineer, which PCB board type is most phone used?

The answer is most smart phone use HDI PCB board, even iPhone.

The long full name of HDI PCB

Different with MCPCB, HDI PCB doesn’t have so many names.

Some green guy doesn’t know the HDI short for.

In fact HDI PCB is short for High Density Interconnector Printed Circuit Board.

But this long full name is used very few.

The density of HDI PCB

To know HDI PCB difference from other PCB board, but what is the differ?

Yes, the biggest differ is density.

You know HDI PCB has very higher wiring density per unit area, some HDI PCBs higher several times than the conventional PCB board.

Finer Lines of HDI PCB introduce

In mobile phone application, the assembly space become smaller and smaller.

This requires the PCB board in phone finer and finer.

Addition HDI PCB design smaller vase and capturer pads and higher than connection pads.

You know in traditional PCB design process, there were many tips from experience before.

But in HDI PCB board design, just experienced is not enough, you also consider many factors that never consider before.

The manufacture process of HDI PCB

During HDI PCB manufacture process, each pic of HDI PCB is made through microwave.

Differ Metal core PCB, HDI PCB have many buried vias and sequential lamination with insulation materials.

And conductor wiring for higher density of routing, to make this type board have long life time.

This feature also meets smart phone requirement, and also the reason why phone manufacturers use HDI PCB assembly.

Why we should use HDI PCB?

Above we have introduced an HDI PCB design process is more difficult than conventional PCB.

Why so many smart phone engineers choose HDI PCB?

The reason is HDI PCB

HDI PCB is used to reduce size and weight, as well as to enhance electrical performance of the device.

The usable area of HDI PCB

To cost down, most phone companies want purchase cheap PCB board.

HDI PCB is the best alternative, high layer PCB or multilayer PCB board.

Even some of the conventional high PCB board have improved its performance, and decrease the price.

But this hardly to meet phone company PCB requirements, cheap price, reliability and performance etc.

Others also read those articles about PCB Purchase:

- Some factors related to PCB assembly quote calculator

- Top 2 factors related to quote my PCB online

- Some unexpected when place a PCB assembly quote

- TS 16949 Automotive PCB Standard Introduce

- Metal core pcb cost is the biggest advantage

- Do you know the metal core PCB thickness?

- Top 7 common senses of HDI PCB definition

- 8 tips guide you find a good PCB supplier

- Top 1: Metal Core PCB Manufacturing Industry experience

- FR-4 PCB base material is the best option for conventional PCB board