Previous post we have discussed LED PCB board design Guidelines [Part 1].

Today we are going to continue to introduce how to design LED PCB board.

SMT Pads design always makes trouble.

Even some LED PCB designer who has experience also may make mistakes.

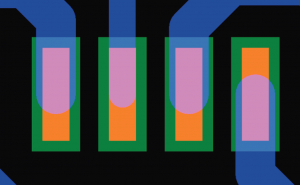

Do Not Route Wide Traces Into Narrow SMT Pads

Traces which terminate at surface mount pads should be narrower than the pad itself.

If the trace is wider, the solder mask aperture, rather than the pad area, will define the area to which surface finish will be applied to the PCB.

The result will be insufficient paste coverage, because the stencil aperture size will match that of the pad only.

Using narrow traces also reduces the heat sink effect which can occur when wide traces are present.

The paste will be applied only to the pad areas, but the mask opening exposes the too wide traces.

The solder will spread to the traces on the 1st, 3rd, and 4th pads, resulting in a poor solder joint.

—

From epectec, original author have all right.

Original title:TOP 10 PRINTED CIRCUIT BOARD DESIGN CHECKS

MCPCB experts recommend top 10 design tips:

- Avoid Placing Vias at the End of SMT Pads

- Do Not Route Wide Traces Into Narrow SMT Pads

- Do Not Route Traces Along Sides of SMT Pads.

- Route All Traces at 90 Degrees or Greater

- Don’t Place Components Too Close to the PCB Outline

- Never Export English-Unit Gerber or Drill Files at 2:3 Decimal Resolution

- Size Your Solder Mask Openings Consistently

- Always Use Direct Connect for Vias

- Size Your Component Hole Thermal Pads Appropriately

- Allow Enough Clearance Between Unsupported PTHs and Adjacent Copper Features on Internal Layers