Discover the wide range of from MC LED Driver Store Shop a large selection of LED strip lights for indoor and outdoor applications, such as under-cabinet lighting,coves, landscapes, vehicles, and more.

Author Archives: Angel-mc

Will Does the Ultra Thin Flex PCB meet Your Needs? Read this article find out the answer. What is ultra thin flex PCB? The ultra thin flex PCB is special PCB type, which is super thin. Construction of ultra thin flex PCBThe ultra thin flex PCB consist of advance protect layer than normal PCB board.The […]

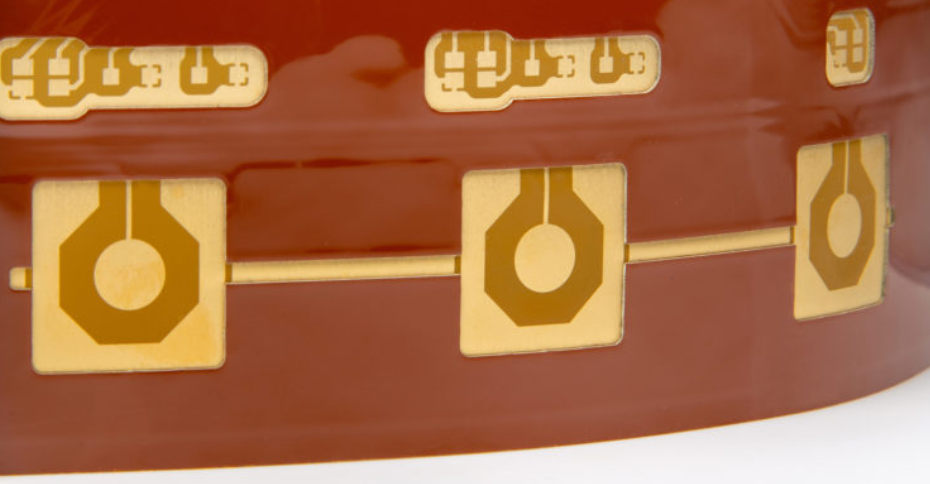

The 5G technology is the future, and more and more product need to update to 5G version. All 5G products require light weight, miniaturization, multifunction and assembly desification. This means those products will require higher requirement, the rigid-flex PCB is the answer. As we know, rigid flex PCB is a type of special flexible PCB […]

Howby, we are going to discuss Flexible PCB Manufacturers in Germany. If you have any question about Germany Flexible PCB Manufacturers. Please comment below, we will response as soon as posible. 5 Flexible PCB Manufacturers in Germany 5pcb.de GmbH. Germany, Nordrhein-Westfalen Andus Electronic Gmbh. Germany, Berlin EES European Electronics Systems. Germany, Hesse Elekonta Marek GmbH […]

Do you know 5G? And what does 5G effect with manufacture industry, especial PCB manufacture industry. This post Angel want to discuss some topic about 5G device. If you have any question about PCB of 5G device, please do not hesitate to contact us. Here we go. The history of 5G The analogy I understand […]

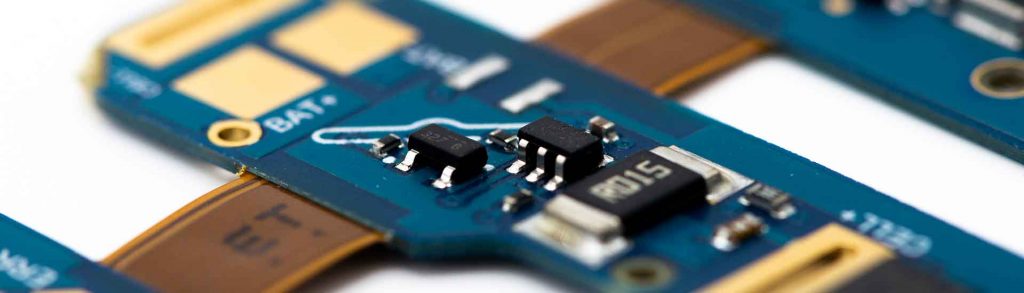

This post let’s discuss Top 5 Advantages and Features of Metal Core Printed Circuit Board (MCPCB). MCPCB Can easily be used for Surface Mount Technology (SMT) Surface-mount technology (SMT) is a method for producing electronic circuits in which the components are mounted or placed directly onto the surface of printed circuit boards (PCBs). A huge […]

Do you know How to Drawing a prototype PCB schematic? This post we are going to discuss How to Drawing a prototype PCB schematic. As we know, there are many electronic technologies in prototype PCB schematic process. We just discuss the main goal at your drawing prototype PCB schematic. Here we go, and keep on […]

This post we are going to discuss the standards of flex PCB. We will combine the advantage from differ flex PCB types and rigid-flex PCB, from the PCB standard engineer eyes. So, please go deep read to know The Advantage of Differ Flex PCB Standard. If you want to learn more PCB standard, please go […]

This post we are going to discuss how Automotive PCB board meet TS 16949 Standard issues. Related TS 16949 Standard post: TS 16949 Automotive PCB Standard Applications TS 16949 Automotive PCB Standard Introduce If you are building for the automotive industry (or want to be), you will eventually need to be certified to the IATF16949 […]

Rigid-flex PCB Designer Introduce Cost We have introduced Rigid-flex PCB Cost comparison of design. Most of the time we just consider the price of Rigid-flexible PCBs design. This post we will discuss how Rigid-flex PCB Designers thoughts. Why Rigid-flexible PCBs design always be more expensive? You are merging multiple boards into one design, only one […]