The biggest difference of double sided flexible PCB

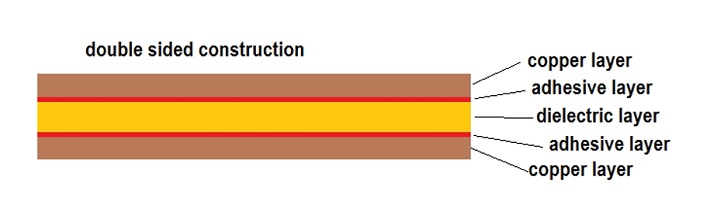

As we know more of a PCB board definition by its layers, especially copper layer number.

Yes, Double sided flexible PCB has two copper plane layers.

And those two copper plane layers always printed line in flexible PCB.

That’s the reason why one of the copper plane layers on the top, and another one is bottom.

In fact, there was a layer of insulating film to separate two copper plane layers.

So traditional double sided flexible PCB construction can avoid Short Circuit.

The adhesive layer of double sided flexible PCB

We have introduced three layers of double sided flexible PCB, two copper plane layers, insulating film.

But none of them have good adhesive ability.

That’s the reason why most PCB boards have to add adhesive layer.

This is as with single sided flexible PCB board design.

So the bonding between the substrate film and the copper conductors is adhesive layer.

In some specially double sided flexible PCB design, the bonding area also can be adhesiveless.

How to design awesome double sided flexible PCB construction

First of all, you should know how to manufacture the holes of double sided flexible PCB.

The first one is through holes drilled.

Usually the size of flexible PCB holes is smaller than metal core PCB board.

So you should take care about it.

Then is plated the hole.

This step is aimed to form conductive vials, and connect two copper plane layers.

That’s the most simple flexible PCB hole process.

The second one is how to create trace patterns.

If you have visit a double sided flexible PCB factory, you may find that two copper plane layer circuits can be create same time.

The first step is imaged two sides.

Then etched the circuits, and create the trace patterns.