There were two types of single-sided flexible circuit constructions.

The first one is the copper can be bonded directly to the dielectric.

And there was no any adhesive material.That the reason why all Flexible PCB have good bending ability.

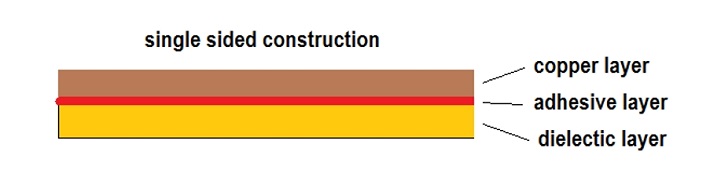

The second one is very differ with the first type constructions of single-sided flexible circuits.

It is out with copper foil bonded to a single layer of Polyimide dielectric film.

The bonding between the copper and Polyimide is usually accomplished with a layer of adhesive.

If you have read our article about multilayer PCB board, you may find that above two constructions are so different.

The copper material of single-sided flexible circuit

Most of copper foil of single-sided flexible circuit are composites.

And those composites are known as adhesiveless substrates.

If you have read our Metal Core PCB manufacture process, you may know the trace of circuit always created some.

In professional words, the creation of the copper pattern is done by photolithography imaging, developing, and etching.

The adhesive and dielectric material of single-sided flexible circuit

The first type single-sided flexible circuit construction is lamination copper foil and dielectric layer directly.

And the second one is created with a subsequent lamination of pre-punched Polyimide bonded as an overlay.

But there were others with special situations.

For example, the photo-imaged solder mask can be defined as a selective dielectric covering on the top layer.

So this time, the dielectric layer of single-sided flexible circuit is soldered mask.