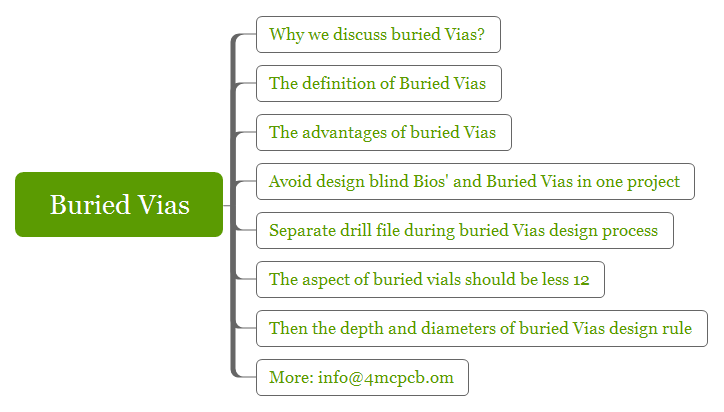

Why we discuss buried Vias?

We have discussed some topic of blind was in the previous paper.

Then Emma will introduce some topic about buried Via.

Most green hands don’t know those two definitions, that’s the reason why Emma recommended read two articles together.

The definition of Buried Vias

A buried via is a via between at least two inner layers, which is not visible from the outer layers.

This definition is differentiated with the blind Vias.

Blind Via is connected outer layer and inner layer circuit.

The advantages of buried Vias

We have known only HDI PCB board have buried Vias.

But why HDI PCB has to design buried Vias?

Those reasons must from the advantages of buried Vias.

From above buried Vias definition, this technology allows more functionality in less board space.

This is why HDI PCB has higher density than conventional PCB boards.

The second advantage is cost effective.

If you want to use rigid PCB to assemble some function produce, you may spend more money.

Even the price of buried Vias PCB board higher than conventional PCB, but HDI PCB is the most effective option.

Some design rules of buried Vias

Avoid design blind Bios’ and Buried Vias in one project

Due to HDI PCB manufacturing cost, higher than than rigid PCB.

Most experience HDI PCB design will suggest avoiding an overlap of blind and buried vias in the layer stack-up.

Likely, avoid blind vice from L1-L4 and simultaneously buried vias from L3-L5.

Separate drill file during buried Vias design process

This rule some with the blind Vias design.

All of two hole drill file should be defined as a separate drill file.

The aspect of buried vials should be less 12

This design rule is very different.

In blind Vias design the aspect just requires less 1.

But in all buried vase design, the aspect should be less 12.

This point ignores by most green hands.

Then the depth and diameters of buried Vias design rule

Some of the blind vase design, the smallest hole determines the buried Vias depth.

And the max distance between the respective inner layers determines the diameters.

4MCPCB experts recommend choosing the inner layers annular rings.

Because the larger you choose the annular rings on the inner layers, the more stable the connection.

4MCPCB experts introduce Blind and Buried Vias