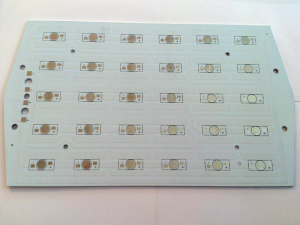

LED TV circuit board manufacturing is a very professional process.

It has very complex PCB manufacturing process.

So Allen wants to make a series articles to introduce how to manufacture an LED TV circuit board.

In fact, most normal LED circuit board also has some process.

Today we are going to discuss the Etching Process of LED TV circuit board.

The easiest manufacturing circuit method of printed circuit board

Though there are many methods available for etching, the most common method used by electronics hobbyists is etched using ferric chloride or hydrochloric acid.

Both are abundant and cheap.

By the way, the above method just use for hobbyists.

If you want to custom LED TV circuit board, you have to choose a high quality MCPCB manufacturer.

The theory of LED TV circuit board etching process

This theory is very important to the PCB manufacturing.

In fact, most of circuit board uses this method to make the wires.

Etching process has to be done to remove unnecessary copper after applying a temporary mask, leaving only the desired copper traces.

Three steps to finish etching LED TV circuit board

#1 Cover the temporary mask

All PCB’s are made by bonding a layer of copper over the entire substrate, sometimes on both sides.

#2 Dip the board to solve

Dip the PCB inside the solution and keep it moving inside.

#3 Finish etching

Take it out at times and stop the process as soon as the copper layer has gone.

After etching, rub the PCB with a little acetone to remove the black colour, thus giving the PCB a shining attractive look.

The LED TV circuit board layout is now complete.