This post will discuss some factors related to the LED PCB solution.

You may think the LED PCB is very simple PCB board.

Yes, if you compare to flexible PCB board It’s construction may more simple.

But if you consider the thermal management, LED PCB board must be a complex process.

To ensure the performance and reliability of our PCBs, we follow a strict process from development to post-production measurement, all within unbeatable timescales.

Better Heat Transfer of LED PCB board

The heat dissipation of the LED PCB board is the most important factor in the product’s lifetime.

Normally LED PCB design will consider use aluminium material.

But how to use aluminium material to make a good performance LED PCB board?

From our heat transfer testing, we have summarized below.

Uses thinner materials re-sulting in an 1,80% reduction in distance from LED chip to Heat Sink.

Easy Assembly for most new LED PCB workers

If you didn’t visit an LED PCB factory, you may can understand this point very clearly.

LED PCB assembly is an important process for most LED lighting products.

Here is a flex PCB kit solution, it’s not match every one manufacturer, but it’s a good reference.

Flex LED PCB Kit includes a pre-assembled rigid fixture which provides solid backing during stenciling and reflow.

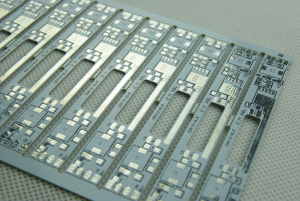

The parts also come palletized in arrays so customers can assemble multiple pieces at a time.

Less Soldering during LED PCB assembly process

In traditional PCB assembly process, there were mostly used solder mask to assembly components.

But during the LED PCB assembly process, even also use solder mask to assembly LEDs.

But in our new LED SMT PCB technology, there were less soldering during the assembly process.

If you want to learn more LED PCB board, news, please follow our website update.