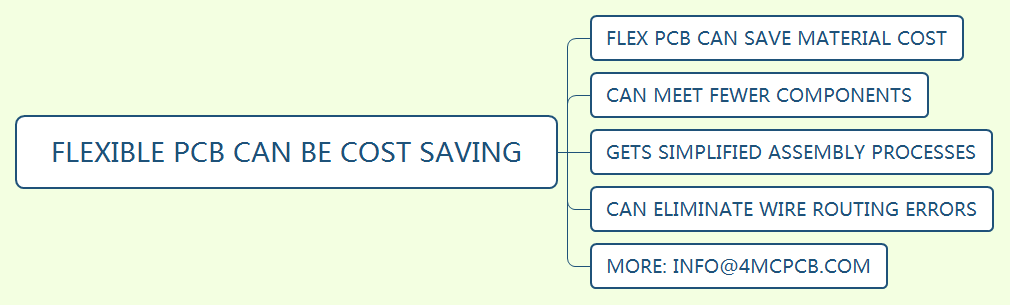

You shoule know the reasons why flexible PCB can be cost saving

We have discussed Metal core PCB are widely applied in special industry.

Many smart home products have become smaller and smarter, this mean that we should choose more smaller PCB board.

The flex PCB or rigid-flex PCB can be reach this requirement.

With the development of flex PCB manufacturing, it’s cost have decreased than before.

So this post focuses on introducing top four reasons why flexible PCB can be cost saving.

Use flex PCB can save material cost

You know flex PCB board made of polyamide, have a much smaller area.

Compare with normal multilayer PCB board, it’s have thinner thickness and flexible bending ability.

In other words, the flex PCB can be design less raw material.

And also reducing the overall finished assembly, packaging size and material requirement costs.

Even the price of Polyimide expensive than FR-4 material.

If you use the FR-4 raw material to manufacture PCB to meet those special requirements, the cost may higher than the flex PCB board.

Use flexible PCB board can meet fewer components

Now most of smart home products have require smaller size.

If you use flex PCB, you can assembly more flexible and require a smaller size.

So use flex PCB can meet fewer components.

Use flex PCB gets simplified assembly processes

Generally speaking the PCB assembly process can affect project cost.

Due to flex PCB can only be installed one way, most of those assembly process must design effective.

In another way the flex PCB assembly process always design simplified.

Not only can reduce flexible PCB assembly errors, but also can save cost mostly.

Use flex PCB can eliminate wire routing errors

Wire rounding errors is the normal design mistake in past decades.

Now we have used computer to aid design, this kind errors has reducing.

In some special PCB board, like HDI PCB design process, the wire routing errors also can be occur.

Due to flex PCB developing, most of PCB designer have require finish flex PCB routing design.