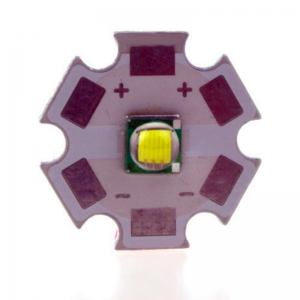

MCPCB Manufacturing Solder mask Process protects PCB circuit

There were many methods protecting the PCB circuit, but Solder mask may the widely use method.

The primary purpose of the mask is to restrict the areas that will be covered with solder.

If the board surface have all covered with solder, then the board may shorten.

It also protects panels from contamination, handling damage and possible electrical shorting during assembly and installation.

How to Solder mask on the MCPCB board?

If you don’t know the normal PCB manufacturing process, you can understand this post have some difficulties.

Anyway, Allen will try to introduce the simple single sided MCPCB manufacturing process.

Solder mask is normally cured by baking in an oven;

however, some fabricators are using infrared heat sources.