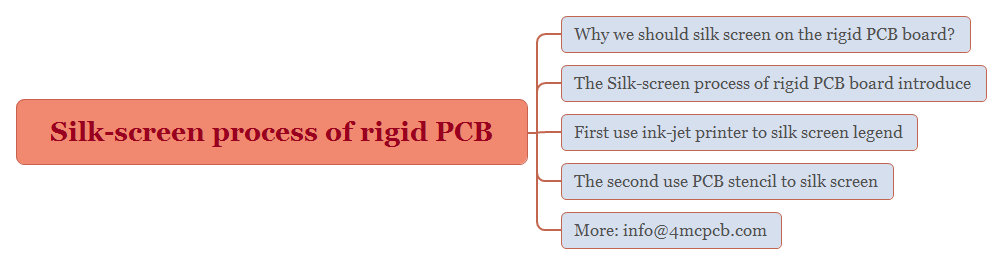

Why we should silk screen on the rigid PCB board?

If you have watched a rigid PCB board, you must see the component legend on the surface.

In fact, it is Silk-screen of rigid PCB, those were used silk screen technology.

So the silk screen legend can help an assembly worker to know the right place of the component.

Also can help electronic product repair to check the rigid PCB and components.

The Silk-screen process of rigid PCB board introduce

You know the rigid PCB technology have developed fast.

Some rigid PCB manufacture method will be changed, like silk screen solution.

This part Emma will introduce two different silk screen legend methods of rigid PCB.

First use ink-jet printer to silk screen legend

In fact, this process is some with other silk screen technology.

Like a conventional paper printer the ink-jet printer sprays minute droplets of ink onto the panel to generate the image.

Some of rigid PCB manufacturers where use ink-jet printers to finish this process.

Now there were many silk screen legend solutions companies.

This means they provide the silk screen solution and the ink-jet printer needs no set-up.

The second use PCB stencil to silk screen

Some small rigid PCB factory uses PCB stencils to finish silk screen.

This silk screen method, process, PCB stencil as a silk screen mould.

If you ask some old silk screen worker, they also named this process as a mould silk screen.

In pass decades, this silk screen method of rigid PCB widely uses.

That is the reason why the legend of rigid PCB is often called the silk-screen.