Most people didn’t know the detail construction of LED PCB, special the function of the dielectric layer.

This post will discuss the dielectric layer LED PCB design process.

First of all you should learn the metal core PCB application.

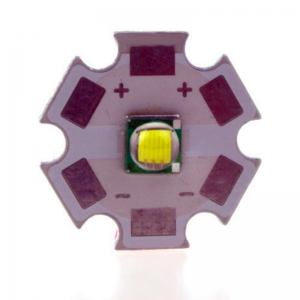

Metal core PCB and standard FR-4 are commonly used circuit board materials in conjunction with Power LEDs.

LED lighting industry, most companies use aluminum PCB in developing new projects.

Due to its perfect heat transfer performance.

The function of dielectric layer of LED PCB board

We have known LED PCB have very good heat transfer performance.

But do you know the reason why LED PCB board have those features.

To explain how is the heat transfer working theory, we have to discuss the dielectric layer of LED boards.

The thermal Clad dielectric is a thin, thermally conductive layer bonded to an aluminum or copper substrate for heat dissipation.

So during the LED PCB designer process, must consider LED PCB heat transfer.

The key to Thermal Clad’s superior performance lies in its dielectric layer.