To answer this question, we have to know the detail of multilayer PCBs.

David doesn’t want to introduce many terminologies to explain how are multilayer PCBs manufactured.

So We will from another point to discuss this topic.

First of all we should know why we need multilayer PCBs.

Now all smart devices have become more and more small, and the performance has improved, most of the reason is that the multilayer PCB have improved.

To increase the area available for the wiring even more these boards have one or more conductor pattern inside the board.

Second is the main issue of multilayer PCBs manufactured.

There were more and more requirements of multilayer PCBs, but multilayer PCB manufacture were differentiated from single or simple PCB board.

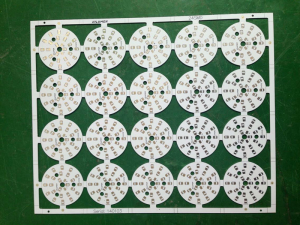

This is achieved by gluing (laminating) several double-sided boards together with insulating layers in between.

The number of layers is referred to as the number of separate conductor patterns.

It is usually even and includes the two outer layers.

Most main boards have between 4 and 8 layers, but PCBs with almost 100 layers can be done.

One more thing of multilayer PCB manufacturer

If you have learned much more about the advantages of multilayer PCBs, you may think all of new smart devices will use multilayer PCBs.

Unfortunately, even though there were many devices use multilayer PCBs, but some new products or devices also use normal PCBs.

David has found a type call example for this.

Large super computers often contain boards with extremely many layers, but since it is becoming more efficient to replace such computers with clusters of ordinary PCs, PCBs with a very high layer count are less and less used.