Will Does the Ultra Thin Flex PCB meet Your Needs? Read this article find out the answer.

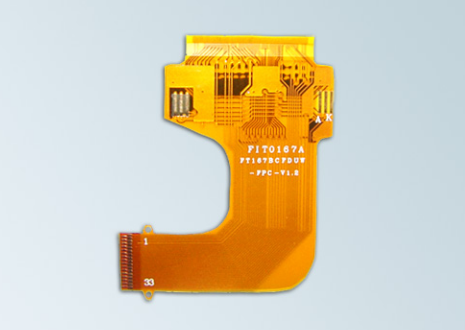

What is ultra thin flex PCB?

The ultra thin flex PCB is special PCB type, which is super thin.

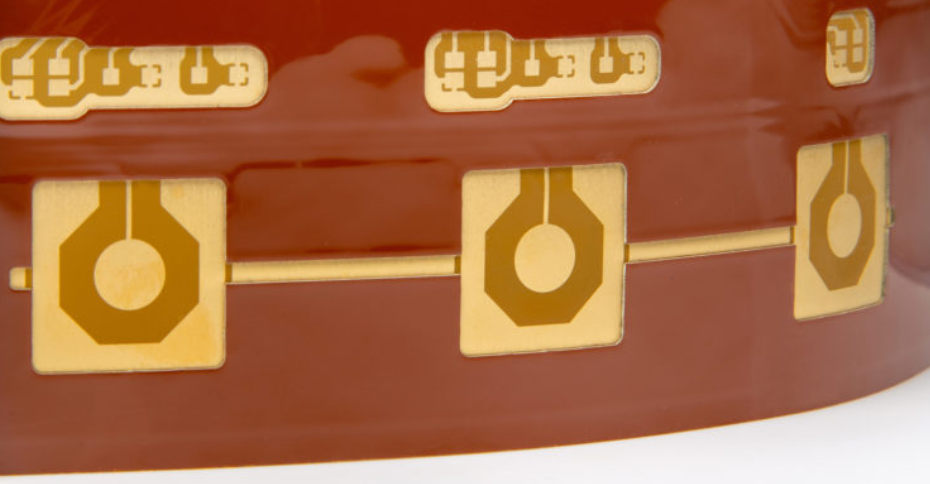

Construction of ultra thin flex PCB

The ultra thin flex PCB consist of advance protect layer than normal PCB board.

The normal PCB board also use the simple solde mask to protect circuits.

The ultra thin flex PCB cover conductors with polyimide, a dielectric layer that protects the circuit, and the effecial better than other type PCB boards.

And other base and cover materials also can be use by ultra thin flex PCB Manufacturers. Most flex PCB board designed to handled a broader range of ambient conditions and harsh evironments.

Advantage of ultra thin flex PCB

As we mentioned that ultra thin flex PCB is super thin, but those flex PCB are able to weather long duty cycles of flexing.This is the biggest advance of ultra thin flex PCB.

Flexing cycles

If PCB designer using suitable material to design the ultra thin flex PCB project, those flxe PCBs also can be made robust enought. Most important is that it with stand millions of flexing cycles. And carrying power and signal withour interruptions.

Customized

All PCB board is a replacement for a ribbon cable, or discrete wiring, special for the ultra thin flex PCB board.

Because all flex PCBs supply customized repeatable routing paths throughout the Flaxible PCB accembly.

High Performance

The ultra thin flex PCB also can reduce service calls due to their greater dependability. In some small device, ultra thin flex PCB is the first option.

The ultra thin flex PCB conbain the low mass and high ductility features.

It’s easy to face high acceleration and/or vibration.

Lower impact from the working conditions

In same working conditions, the solder joints and the compennents have bigger impact by the evironment.

So,the stress and impact on ultra thin flex PCB are far lower than Rigid PCB.

If you have any question, Get A Quick Quote Or Chat.