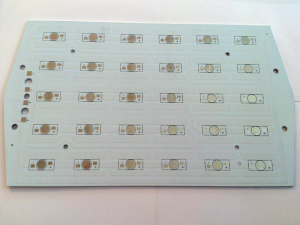

This post we are going to discuss UV LED PCB exposure.

We discuss may not focus LED PCB manufacturing, but also discuss the choose of LED PCB manufacturing equipment.

So why we should choose UV LED PCB exposure?

The first factor is the efficiency of PCB manufacturing.

You know the MCPCB manufacturing is very traditional produce technology.

There were many people don’t know the efficient of UV LED PCB exposure.

LEDs are far more energy efficient than either incandescent or fluorescent lamps offering between 5-10 times more efficiency, making them cheaper to run and kinder to the environment.

Secondly factor is the lift span of UV LED PCB exposure

LEDs have a far greater life span than the other types of lamp measured in decades rather than months.

Finally, factor is the safer of UC LED PCB exposure

The frequencies being emitted are also in a tight band making UV LEDs safer than the traditional UV tubes.

They also (unlike fluorescent tubes) do not contain mercury.